SARRALLE has reached a major milestone in industrial decarbonization with the successful launch of a pioneering green hydrogen combustion system at ArcelorMittal’s Olaberria plant—one of Europe’s most advanced steel production facilities.

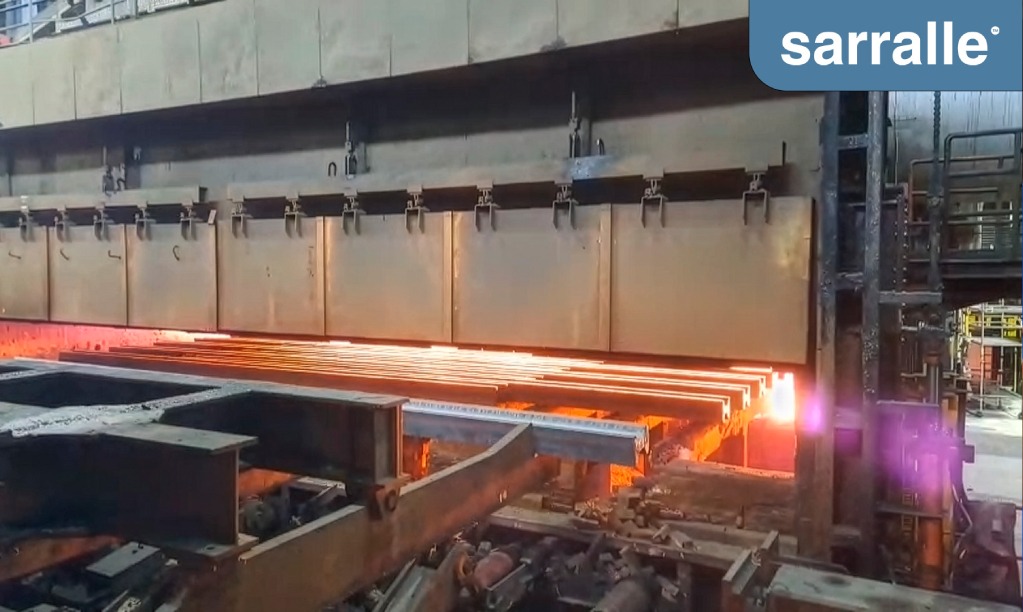

This project marks a breakthrough in integrating green hydrogen and oxy-combustion technologies into steelmaking. The entire system, designed, manufactured, and installed by SARRALLE, allows the rolling mill’s reheating furnace to run on 100% green hydrogen instead of natural gas. This change fully eliminates emissions from the combustion process.

Developed in close collaboration with Nippon Gases, the system replaces traditional air–natural gas burners with hydrogen-based oxy-fuel burners. This significantly boosts thermal efficiency while guaranteeing cleaner, more sustainable steel production. Since hydrogen combustion produces only water vapor, this technology is a vital enabler of zero-emission processes.

Reheating furnaces are massive energy consumers in steel plants, often accounting for up to 80% of a facility’s fuel. This innovation is a crucial step toward decarbonizing the steel sector, which currently contributes about 9% of global emissions.

“This project is a key step toward the future of the steel industry. It proves that green hydrogen combustion technology is already a reality and that decarbonizing industrial processes is possible,” says Itsaso Auzmendi-Murua, Head of the Hydrogen Business Line at SARRALLE.

With this accomplishment, SARRALLE solidifies its leadership in hydrogen-based industrial solutions, underscoring its commitment to innovation, energy transition, and a sustainable future for the steel industry.