VSPARTICLE, a leader in advanced nanomaterial manufacturing, has announced peer-reviewed validation of its nanoporous catalyst layer technology, confirming its potential to eliminate one of the most critical bottlenecks in green hydrogen production — the global shortage of iridium used in proton exchange membrane (PEM) electrolyzers.

In collaboration with Plug Power Inc. (NASDAQ: PLUG) and the Center for Clean Hydrogen at the University of Delaware, directed by Professor Yushan Yan, the project demonstrated exceptional performance while reducing iridium loading by up to 90% compared to conventional electrodes.

The results, presented at the Electrochemical Society (ECS) Meeting in Chicago, exceeded the U.S. Department of Energy’s (DOE) 2026 targets for both iridium utilization and electrolyzer efficiency. These findings provide a clear pathway toward achieving green hydrogen production costs of $1 per kilogram — making it competitive with fossil-based hydrogen from steam methane reforming (SMR), which typically costs $1.50–$2.50/kg (source: IEA).

“This data, combined with the scalability of our technology, transforms a fundamental constraint into a scalable solution,” said Aaike van Vugt, CEO of VSPARTICLE. “Our dry deposition process is not just an improvement on spray coating — it’s a complete redesign of how electrodes are made, using iridium with near-optimal efficiency. This is the missing link the industry has been waiting for to scale PEM electrolysis to multi-gigawatt levels without running into an iridium shortage.”

“The performance achieved at 0.4 mg/cm² is remarkable,” added Dr. Thomas Valdez, Senior R&D Manager at Plug Power. “VSPARTICLE’s electrodes deliver the durability and current density needed for commercial operation. This level of iridium efficiency is crucial for Plug’s cost-reduction and scaling goals.”

Revolutionizing Electrolyzer Economics

PEM electrolyzers are preferred for their ability to operate flexibly with renewable energy, but their reliance on iridium — one of the rarest platinum group metals with a global supply of only 7–8 tonnes per year — has limited large-scale adoption. Traditional coating processes waste significant amounts of this precious material, requiring up to 1–2 mg/cm² of iridium.

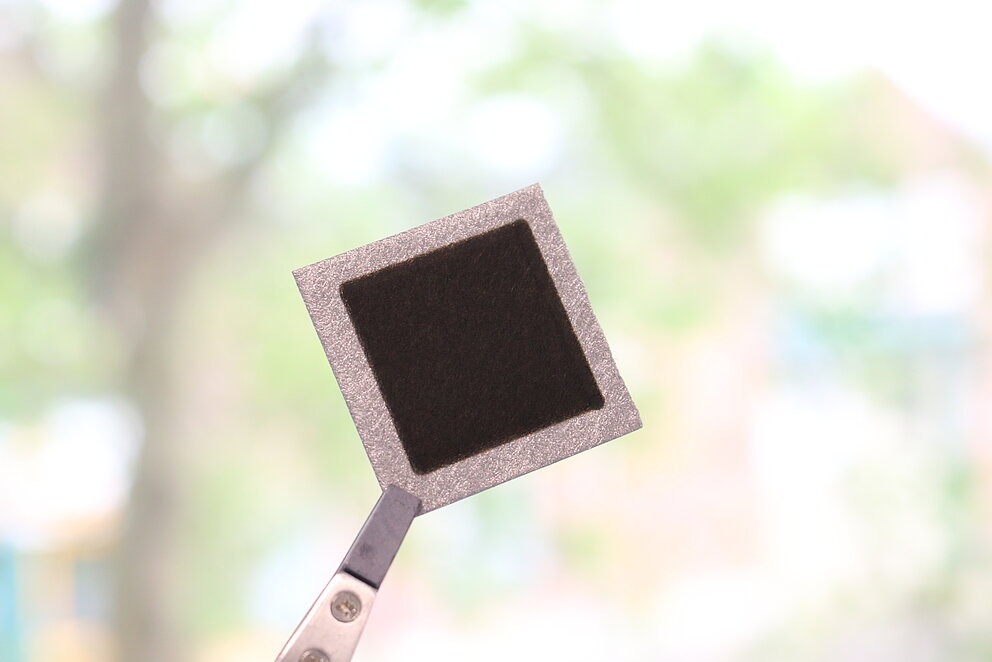

VSPARTICLE’s spark ablation deposition technology creates a highly uniform, nanoporous catalyst layer without the use of PFAS-based ionomers or solvents. This approach maximizes the electrochemical surface area (ECSA), improves metal utilization, and simplifies both manufacturing and recycling.

Combined with the rapid decline in renewable electricity costs — down 90% for solar PV in the past decade (IRENA) — this technology could accelerate the DOE’s “Hydrogen Shot” initiative, achieving cost parity with fossil-based hydrogen years ahead of schedule.

Scaling Toward Industrial Adoption

VSPARTICLE is now expanding its in-house production capacity to support pilot and early commercial programs with multiple leading PEM electrolyzer manufacturers. Several partners have scheduled commercial-scale testing in 2026.

“This breakthrough directly addresses the biggest materials challenge in PEM electrolysis,” said Professor Yushan Yan, Founding Director of the Center for Clean Hydrogen. “Combining ultra-low iridium use with proven durability de-risks next-generation electrolyzer manufacturing. If widely adopted, this technology could prevent a global iridium shortage and fundamentally reshape the economics of green hydrogen production.”

About VSPARTICLE

VSPARTICLE is a global innovator in nanoparticle generation and deposition systems, enabling the creation of next-generation functional materials. Its proprietary modular platform allows precise, scalable production of advanced nanostructures, powering innovation across energy storage, catalysis, and sensor technologies.

With its nanoporous catalyst layers, VSPARTICLE has set a new industry benchmark for performance, reproducibility, and design flexibility, helping bridge the gap between laboratory innovation and industrial-scale manufacturing. Through its technology, VSPARTICLE is accelerating the global transition toward a more sustainable, efficient, and circular hydrogen economy.